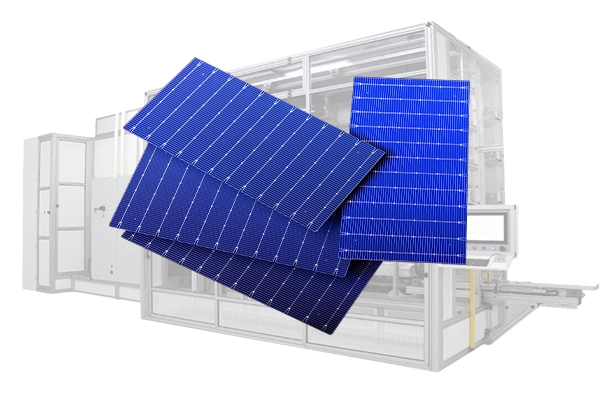

The 8000 Platform by ECM is a state-of-the-art, multi-chamber, horizontal batch furnace specifically designed to meet the demands of high-volume industrial production in the solar cell industry. It supports all advanced thermal processes required for high-efficiency solar cell manufacturing — including poly-Si stack deposition by LPCVD, low-pressure POCl₃ and BCl₃ diffusion, annealing, and more.

With an impressive throughput capacity of up to 13,200 M10 wafers or 12,000 G12 wafers, the 8000 Platform delivers best-in-class performance, combining exceptional process uniformity with optimized cycle times for maximum productivity and yield.

The modular design of the 8000 Platform makes it an equally powerful tool for research and development. Each process chamber can be independently configured, enabling all cutting-edge thermal processes to be run on a single piece of equipment. Thanks to the identical reactor architecture used in both R&D and production environments, the platform ensures a smooth, fast, and risk-free scale-up from lab-scale innovation to full-scale manufacturing.

Each reactor can be custom-equipped with a wide variety of gaseous and liquid precursors, and supports a broad process temperature range from 200°C to 1300°C, making it one of the most versatile and future-proof solutions on the market.