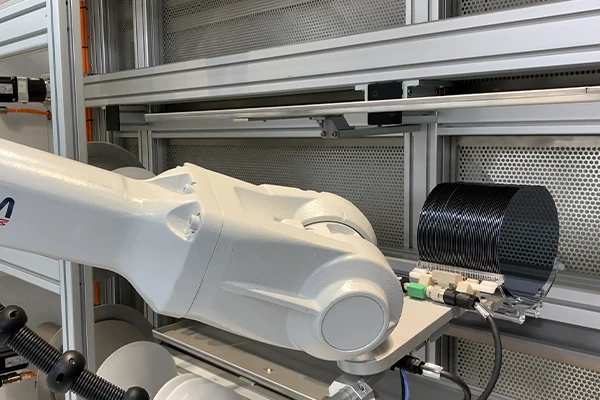

DF-Series are ECM Greentech batch-type, horizontal tubular furnaces for mass-production. Key characteristics of this furnace are: precision semiconductor processing combined with industrial process control, integration modularity, and a user-friendly interface. Each populated chamber can be independently configured and operated in a large range of atmospheric, sub-atmospheric or low pressure processes. The DF furnaces can also handle multiple gases and liquid precursors with a temperature range from 200 to 1300°C. Its modular design allows to meet a large range of clean thermal treatment for industrial facilities.

- DF5303-S150: 3 Tubes – up to 150mm wafers size

- DF5304-S150: 4 Tubes – up to 150mm wafers size

- DF6303-S200: 3 Tubes – up to 200mm wafer size

- DF6304-S200: 4 Tubes – up to 200mm wafer size