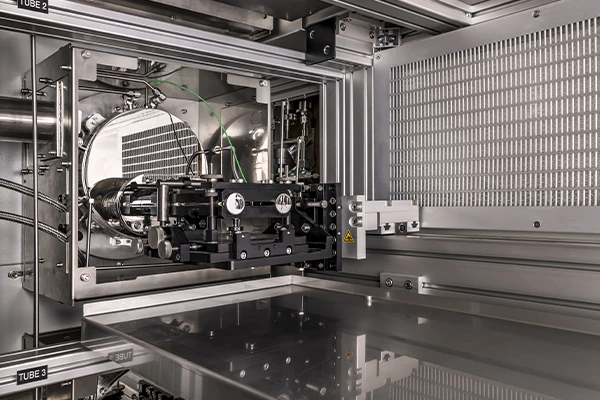

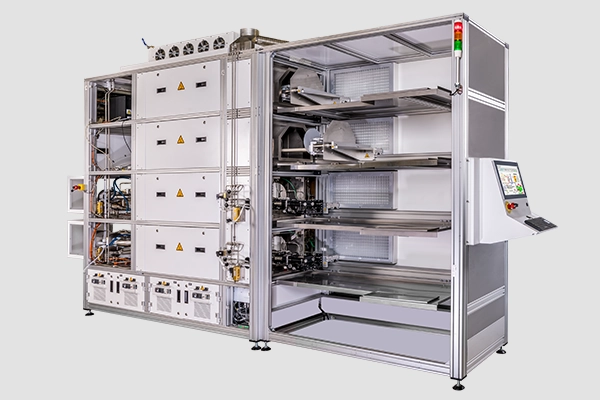

The TUBESTAR solution is a flexible & compact batch-type, single or multi-chambers horizontal furnace offered by ECM Greentech. Key characteristics of this equipment are: High precision semiconductor processing combined with industrial process control, integration modularity, and a user-friendly interface. Each populated chamber can be independently configured and operated in a wide range of atmospheric, sub-atmospheric or low pressure processes. The TUBESTAR furnace can also handle multiple gases and liquid precursors with a temperature range from 200 up to 1300°C. Its modular design allows to meet a large range of clean thermal treatments for universities, research laboratories, and pilot production facilities.

TS150-XT: up to 150mm wafer size

TS200-XT: up to 200mm wafer size

X = chamber/level qty from 1 to 4