The PV1300 furnace is a directional solidification furnace ideal for G8 silicon ingot crystallization up to 1500 kg offered by ECM Greentech. It is adapted to mass production requirements. The design of our 3 heaters hot zone and innovative cooling device makes this furnace the most advanced DS furnace on the market. PV1300 furnace design has been developed for Crystalmax® cast-mono technology to grow fully <100> oriented G8 ingots up to 1500kg and gives the capacity to produce high ingot quality suitable to process high efficiency solar cells like PERC and Passivated Contacts technologies. It features optimised production cost due to high silicon feedstock yield, fully automatic thermal cycle, low maintenance cost and low electrical consumption and low carbon footprint. PV1300 furnace design is suitable with large size wafers production from M2 to M6 and M12 wafers.

Technical Sheet

| Effective dimensions | 3940mm*4910mm*4910mm | |

| Features | Vessel | Water cooled double walls made of stainless steel (Cold wall technology) |

| Vacuum | Ultimate vacuum level 1.10-3mbar Working vacuum level: from 1.10-2 to 1.10-3mbar | |

| Pressure | Partial pressure of Argon neutral gas Maximal pressure patm+50mbar | |

| Maximum temperature | 1550°C (1575 °C) | |

| Heaters | 330 KW, 3 heating zones | |

| Side | 110 KW | |

| Top | 110 KW | |

| Bottom | 110 KW | |

| Safety | Optimised design to limit the consequences of a silica crucible breakage | |

| Maximum heating rate | 500 °C/hour | |

| Heating elements | Graphite | |

| Insulation casing | 60 mm graphite | |

| Ingot Features | ||

| Dimensions | G8, suitable to cut 64 bricks (156×156 mm²), compatible with upgraded wafer size M2 to M12 | |

| Weight | From 1100 to 1500 kg | |

| Growing technology | CrystalMax® cast-mono, HP-multi or multicrystalline | |

| Ergonomics | ||

| Loading | Bottom loading /unloading, safe and easy | |

| Supervision | Touchscreen interface | |

| Options | Operation modes | Fully automatic thermal cycle of manual mode |

| Options | Accelerated / forced cooling | |

| Integration | Turnkey Line | |

'.get_the_title().'

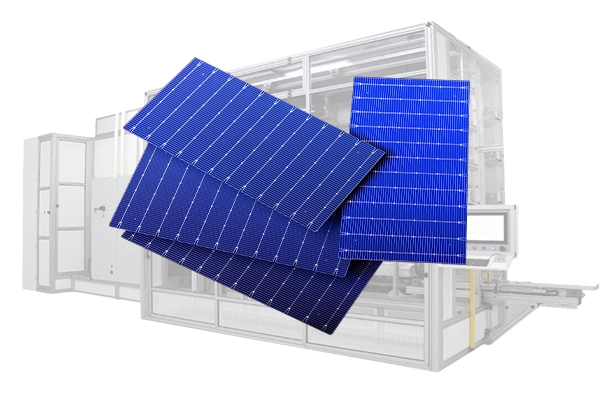

Solar Cell Manufacturing

Solar Cell Manufacturing

Batch Type Horizontal Tube Furnace IRD8000

'.get_the_title().'

PV 20 Directional solidification furnace G1

'.get_the_title().'

PV80 Directional solidification furnace G2

'.get_the_title().'

PV600 Directional solidification furnace G6

'.get_the_title().'

PV1300 Directional solidification furnace G8

'.get_the_title().'

SOLARLAB

SOLARLAB

Batch type vertical Furnace

'.get_the_title().'

TUBESTAR