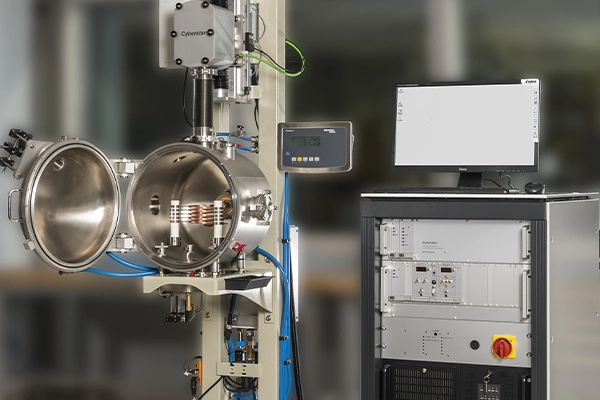

ECM Greentech offers crystal growth furnaces that capable of growing sapphire crystals using the Edge Defined Film Fed Growth (EFG) method. The standard heating method is inductive; however, it can also be equipped with Cyberstar resistive heating elements. Several sizes are available to meet laboratories requirements as well as R&D centers. Trust ecm greentech for crystal growth expertise and don’t hesitate to contact our team for your projects.

Technical Sheet

| Effective dimensions | 400*60*6 (L*W*T) 600*150*6 (L*W*T) |

| Features | Various Crystal sizes up to 60 kg Cyberstrar precise pulling head Equipped with quartz (or sapphire) window view ports Resistive or inductive heating Operating security loop system Water cooled (working temperature in the reactor up to 2600 °C) Fully computerized heating process Chamber capabilities for primary and secondary vacuum |

| Options | Weighing device up to 60 kg Added crucible translation ( manual or automatic) Precise pressure regulation system Controlled mass flow of diffrent atmosphere gases |

| Integration | Possibility of robotics integration |

'.get_the_title().'

Silicon Carbide Crystal Growth

Silicon Carbide Crystal Growth

PVT Furnace

'.get_the_title().'

Edge-defined Film-fed Growth (EFG)

'.get_the_title().'

Micro Pulling Down (MPD) Micro Pulling Down Crystal Growth Furnace

'.get_the_title().'

Laser Heated Pedestal Growth (LHPG)

'.get_the_title().'

MF3000 XENON LAMP furnace

MF3000 XENON LAMP furnace

OPTICAL VERTICAL FLOATING ZONE

'.get_the_title().'

MF2400 Hallogen lamp

MF2400 Hallogen lamp

optical horizontal floating zone furnace

'.get_the_title().'

Vertical 3 zone Liquid Phase Epitaxy (VLPE)

'.get_the_title().'

Liquid Phase Epitaxy (LPE) Application Crystal growth

'.get_the_title().'

Bridgman High temperature Bridgman furnace

'.get_the_title().'

Tetra Arc High temperature melting and crystal growth Arc furnace

'.get_the_title().'

Kyropoulos Kyropoulos crystal growth machine

'.get_the_title().'