Cyberstar Czochralski puller furnaces, offered by ECM Greentech, come in a variety of sizes, heating power elements and current with the capability of producing up to 100 kg single crystals under controlled partial pressure of oxygen and/or inert gas. The heating technology can be inductive or resistive depending on the process requirements and can reach a working temperature up to 2300°C, with a crucible diameter up to 400 mm. All machines are equipped with the precise and stable Cyberstar pulling head having a conversion rate of 0.01 to 100 mm/h translation speed. Due to the use of an intuitive and user friendly Cyberstar pulling software, full monitoring and control of the growth is made possible. A predefinition of the crystal geometry through the dedicated software window enables a fully automatic growthe of the crystal after the dipping of the seed. A full range of design are available for the Czochralski puller which makes it and solution for laboratory use in universities and R&D centers, and also can meet the requirements of industrial production.

– Oxypuller 20-04 industrial puller. Capability of producing single crystals up to 20 kg (chamber topology : vertical axis, front door opening)

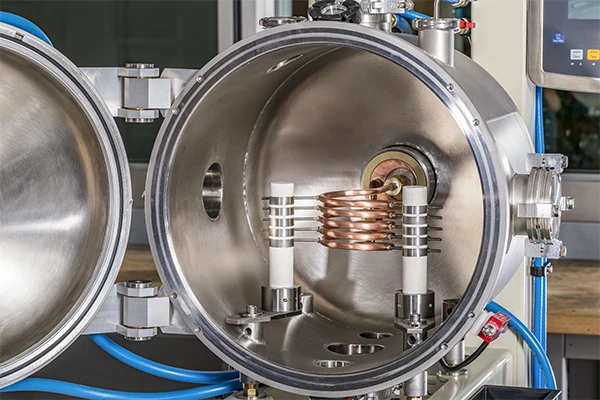

– Oxypuller 05-03 research and development puller. Capability of producing single crystals up to 5 kg (chamber topology : horizontal axis, front door opening).

– Mini Oxypuller: Capability of producing single crystals up to 300 g (chamber topology: horizontal axis, front door opening).

– Oxypuller 20-04: Capability of producing single crystals up to 100 mm diameter (chamber topology: vertical axis, front door opening).

– Oxypuller 30-06: Capability of producing single crystals up to 150 mm diameter (chamber topology: vertical axis, opening along an equatorial plane).

– Oxypuller 30-08: Capability of producing single crystals up to 200 mm diameter (chamber topology: vertical axis, opening along an equatorial plane).

– Oxypuller 30-10: Capability of producing single crystals up to 250 mm diameter (chamber topology: vertical axis, opening along an equatorial plane).