ECM Greentech supports you in your projects to install equipment in the renewable energy sector, with its furnaces for the manufacture of photovoltaic panels and green hydrogen. The ECM Greentech brand, from ECM Group, also offers a range of furnaces dedicated to semiconductor and crystal growth. Trust ECM Greentech for a turnkey production line.

Our PV applications expertise.

Mono Silicon

ingot growth

TECHNOLOGY CZ PULLER

The crystallization of silicon is a crucial step in the PV manufacturing process. Being the first step in shaping the silicon substrates, it impacts the subsequent manufacturing steps and overall efficiency potential for the final solar cell.

The crystallization of silicon being our

core expertise; we stand with our customers to reach the best industry performances.

High quality

Wafers

SMART MANUFACTURING

Large size wafer, full or half cut, down to low thickness for high productivity & efficiency.

N-Type Solar

Cells

TOPCon, XBC, TANDEM

Flexible processes platform for high performance solar

cells manufacturing :

- POCL3 diffusion

- Annealing

- Phosphorus doping

- LPCVD for polycrystallin silicon

ECM Greentech strives to develop leading edge technologies from laboratory to industrial scales. Choosing ECM Greentech is to make sure you benefit from the best technology available.

A strong solar expertise and background.

ECM Greentech is specialized in designing, manufacturing and commissioning equipment and turn-key lines for the renewable energies for many years. ECM Greentech has a strong heritage in the development of silicon crystallization industrial furnaces – as its unique CrystalMax process has been a world reference for many years.

ECM Greentech keeps on pushing innovation to the market and collaborating with renowned partner such as the CEA-INES, national solar R&D institute.

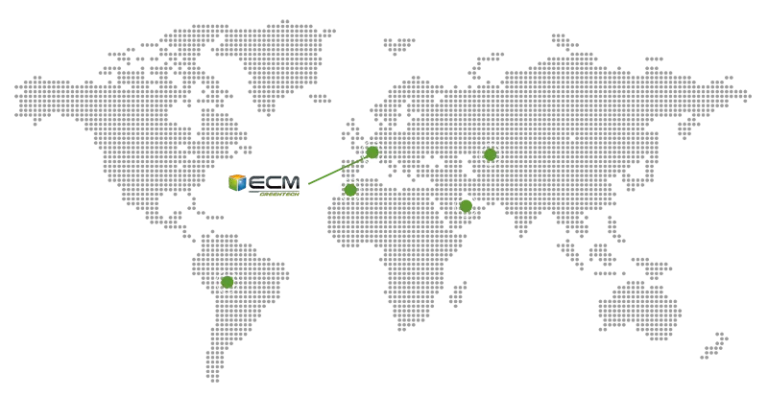

Some of our PV turn-key line

installations.

ECM holds an expertise in large project management, from turn-key line engineering until starting up of the equipment, including technology transfer and process adjustment, training and warranty. ECM has pioneered the development of industrial size silicon casting furnaces

since the 80’s. With a strong industrial focus, ECM kept increasing the capacity and efficiency of its equipments as well as providing innovation. Our technology reaches one of the highest yield and quality in the industry. Whatever the scale of your project (industrial line, pilot installation or laboratory line) we offer you our knowledge and experience.

- Li-ion battery cathodic material line in Bolivia

- Photovoltaic (ingot to module) line in Kazakhstan

- R&D ingot & wafer line in Qatar

- Photovoltaic module line in Morocco