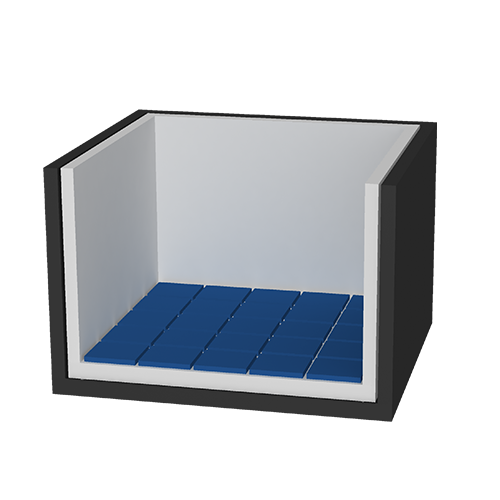

01

The crucible is loaded with reusable mono-seeds for better cost-effectiveness

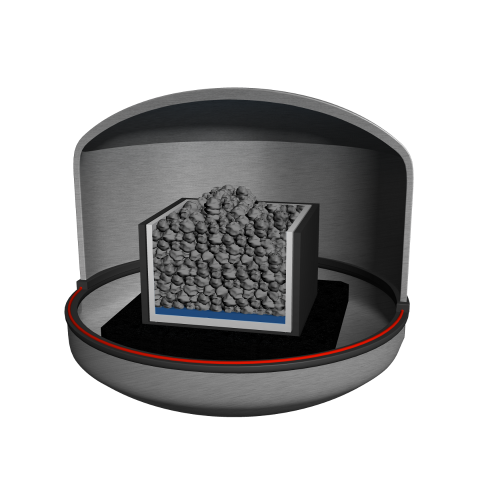

02

Polysilicon chunks are loaded on top of the mono-seeds, from 450Kg to 800 Kg of total load high capacity

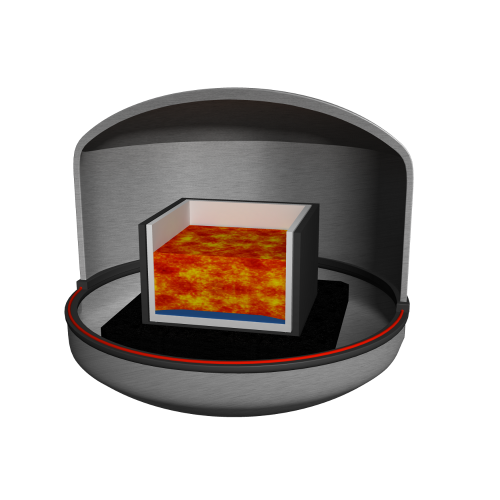

03

The polysilicon melts and part of the mono-seeds remain solid thanks to a controlled heat extraction flow

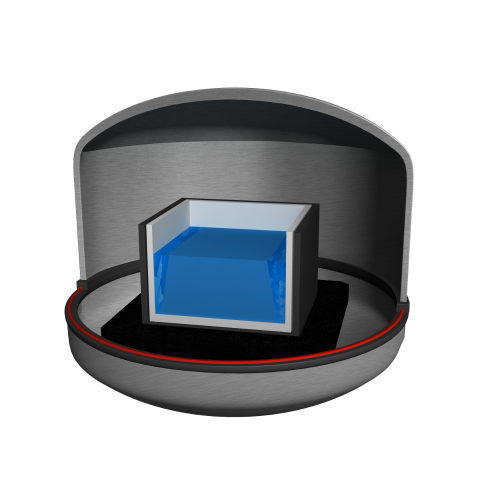

04

A controlled directed solidification delivers a high ingot quality

The furnace design combined with a specific process make CrystalMax® a veritable innovation :

ECM PV600 CrystalMax®

-

Three independent hot zones for high control over the process

-

Innovative cooling device for homogeneous and controlled heat extraction

CrystalMax® process

-

Specific seeds preparation and arrangement : key elements for reaching the highest and most consistent crystal quality throughout the ingot

-

Crystallization recipe by ECM : partial seeds melting and adapted growth for the best crystalline quality

High cell efficiencies

CrystalMax® material has a very high crystalline quality. Alkaline texturing (KOH) allows for excellent optical properties. Thus, CrystalMax® wafers are compatible with all major high efficiency cell technologies (PERC, n-type PERT, bifacial, IBC) giving high cell conversion rate close or equal to the one of Czochralski mono wafers.

Low manufacturing cost

CrystalMax ® offers an attractive TCO (Total Cost of Ownership):

- Crystallization cost similar to HP multicrystalline

- Cost effective diamond wafering of CrystalMax process (lower production cost, lower kerfloss, thinner wafers)

- Full compatibility with diamond slicing method and allows for regular alkaline (KOH) wafer texturing.

- Capital efficiency thanks to high production capacity (>12MW per furnace in G6 – 20MW for the G8): ECM furnace is 3 times more productive than a CZ puller

Full square effect

CrystalMax ® wafers come always full square compared to CZ mono pseudo square wafers where corners are lost.

This extra active surface means more power per wafer. Moreover, it is more cost effective to increase the wafer size with an ingot casting process such as CrystalMax ® rather than a CZ mono process.