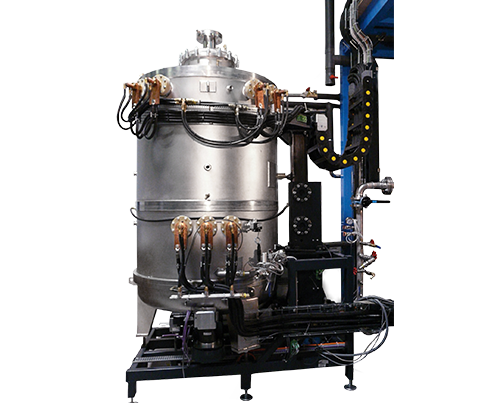

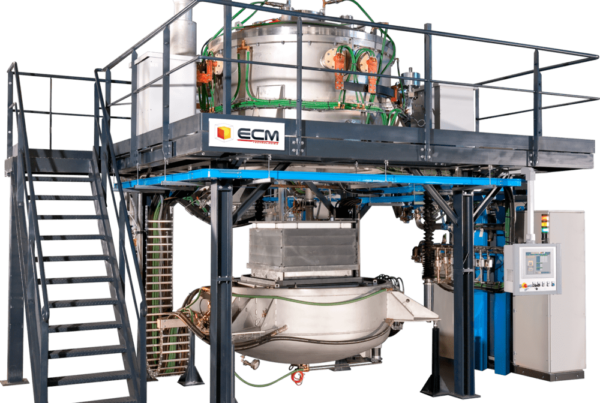

Cyberstar MF2400 is a high temperature Hallogen Lamps based optical horizontal floating zone furnace, offered by ECM Greentechs, to growth garnet single crystal size up to Ø5mm, length 5mm, at up to 2400°C. Heating energy is obtained by focusing light on a small area of the processed rod using high efficiency reflective and concentrating mirrors. The furnace operates based on the floating zone technique using one rod of the grown material, or a seed and feeding rod to provide the melted drop. Both of these solutions are possible thanks to the independent vertical conversion between the upper and lower holders in the furnace. The movement of the upper and lower rods is perfectly synchronized using the Cyberstar control software, which is included with the furnace. It can be used to obtain crystal rods or crystal fibers, at pressure up to 1.5 or 10 bar by using related dedicated chamber. The specific design of the furnace makes it ideal for laboratory use, universities, and R&D centers.

Technical Sheet

| Features | High Temperature / best uniformity => => Elliptic mirrors from massive pre-shaped thick aluminium plates & gold plated => superb infrared reflectivity (conception from base studies by the Astronomy laboratory in Grenoble). |

| Excellent process repeatability => highest precision of device & translation devices | |

| Large environment and treatment range => versatile and flexible concept from low pressure up to 1.5 and 10 bar. | |

| High success / premium quality crystal growth => unique & versatile proprietary process control software | |

| Strong install base in both laboratories and industries | |

| Your crystal growth partner for over 30 years | |

| Operative pressure: – Standard chamber: from primary vacuum low pressure up to an absolute pressure of 1.5 bars – 10 Bar chamber option : from primary low pressure up to an absolute pressure of 10 bars. |

|

| Atmospheres (vacuum, inert gas, reductive and oxidizing atmospheres) | |

| Left & right elliptic mirrors for horizontal light desity of 600W/cm2 for cylindrical rod (12.5mm diameter) | |

| Left & right Hallogen lamp each 1000 W or 2000W, 28K or 56K lumens with long life-time | |

| Shutter device to adjust the ligh flux diameter | |

| Synchronized and high precision upper and lower translation and rotation pulling system with large range of speed monitoring | |

| Primary pump and vacuum circuit | |

| High resolution color digital CCD camera with IR filters for visual control and video recording of the crystal growth process | |

| Temperature measurement by pyrometer | |

| Options | 100 Bar pressure chamber Spare parts set upon request |