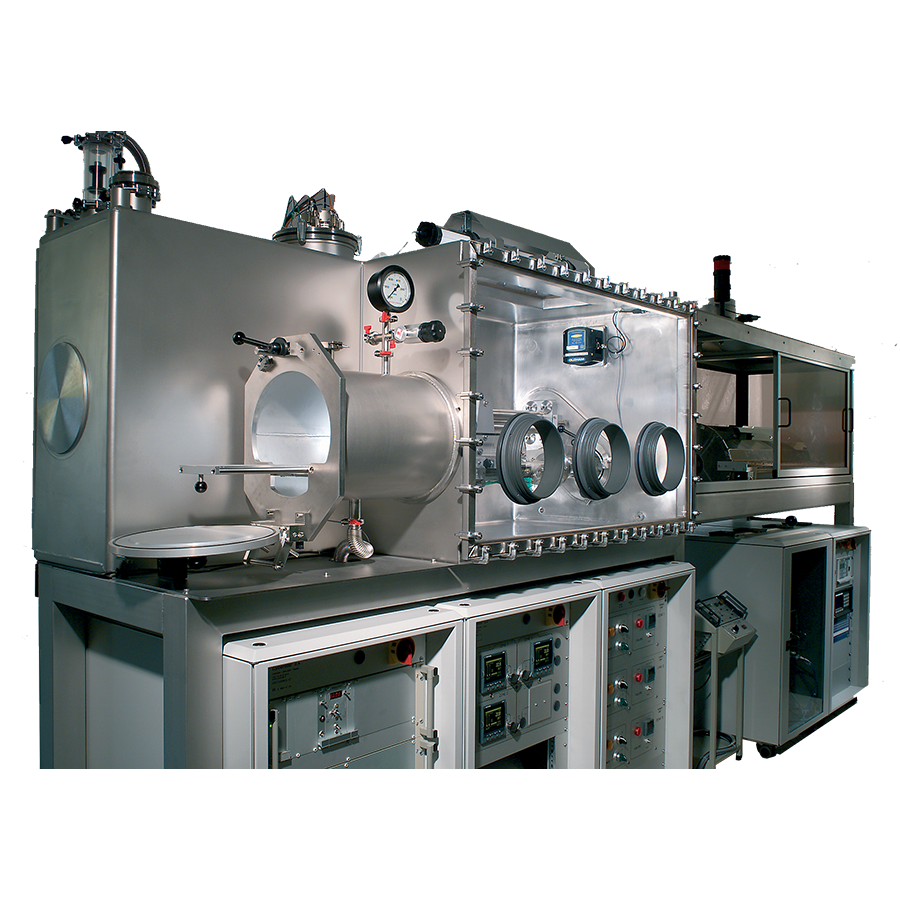

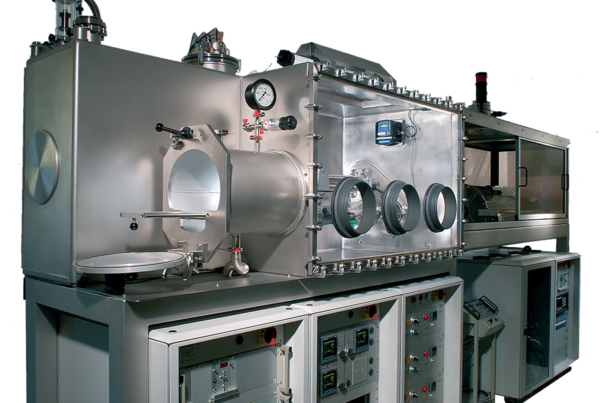

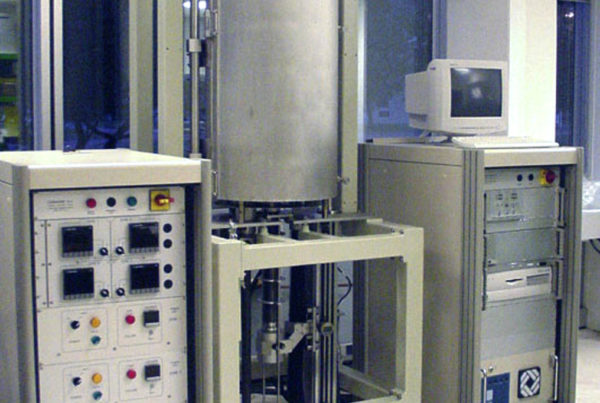

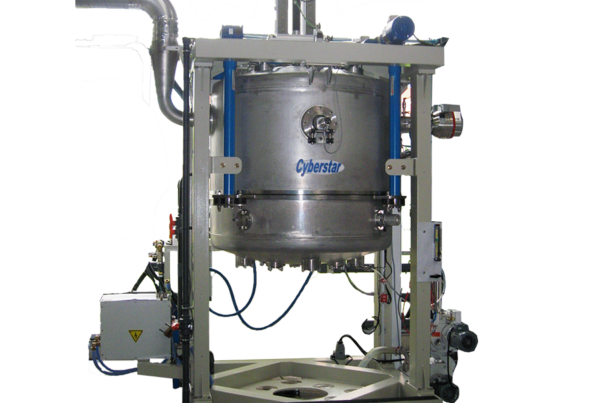

Cyberstar Liquid Phase Epitaxy Furnace, offered by ECM Greentech, is a liquid phase epitaxy installation for II-VI crystals. It is mainly utilized for the deposition of device quality Cadmium Telluride, other II-VI binary and ternary compounds, or other III-V compounds. The process involves the popular graphite boat slider technique. The furnace is optimized for high stability, low thermal inertia, and is able to homogeneously heat up the large graphite boat necessary for handling a 40 x 60 mm2 sample.

Technical Sheet

| Effective dimensions | 20 x 25 mm2 36 x 38 mm2 40 x 60 mm2 |

|||

| Features | Flushed by the neutral gas | Pressure adjustable from low to atmospherique pressure | ||

| Reactor | High purity quartz External diameter 110 mm Boat supported by the very stiff internal tube (no flexion) Well studied gas circulation for optimum uniformity around the boat |

|||

| Furnace | Four zones low inertia furnace, controlled by three temperature controllers and three power stages (standard) In the case of the three temperature controllers configuration, the two central zones of the furnace are connected |

|||

| Decreasing temperature speed | 10 °C / minute at 600 °C 5 °C / minute at 250 °C |

|||

| Horizontal translation of the push rod | Adjustable from 0.06 up to 60 mm/second | |||

| Pumping station | Dry pump : 5.7 m3 /h Typical ultimate vacuum : 7. 10-2 mbar Turbo molecular pump : ISO 63 flange Inlet pumping speed N2 : 65 l/s Ultimate vacuum : 10-6 mbar |

|||

| Gas purification system | Two different gas channels N2 and H2 (other on request) Output : oxygen content in the purified gas : better than 50 ppb for an input gas purity in the range of 1 ppm of O2 Maximum allowed input gas purity : 5 ppm Flow meters on each channel : 5 normal liters per minute maximum (other range on request) |

|||