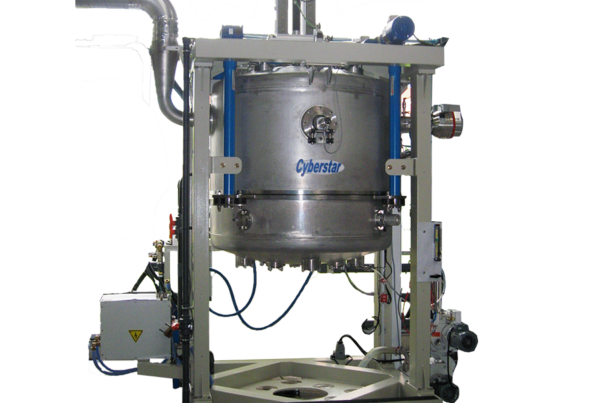

Semco ACTISTAR is the compact batch-type, vertical Single very-high-temperature furnace, offered by ECM Greentech and dedicated to post-implant anneal of SiC & GaN wafers. Key characteristics of this furnace line are: high performance temperature treatment combined with industrial process control, integration modularity, and a user-friendly interface. The applied heating technology alloys very fast heat rate for best uniform sheet resistance and shorter cycle times. The ACTISTAR furnace can also handle multiple gases with a temperature range from 200 to 2050°C. Its modular design allows to meet a large range of clean thermal treatment for R&D and Pilot production facilities.

AS150: up to 150mm wafer size

AS200: up to 200mm wafer size